Bionic Bulldogs #21502

We are team 21502, the Bionic Bulldogs from North Carolina. We are part of a five-team group called Creekside Robotics. This is our team's third season together. Some of us came up from the middle school teams in Creekside, and others started on the high school teams. Our middle school teams are Bots by the Creek 15707 and Boltiverse 21490. Our fellow High school team is Entropic Fluctuations #19410.

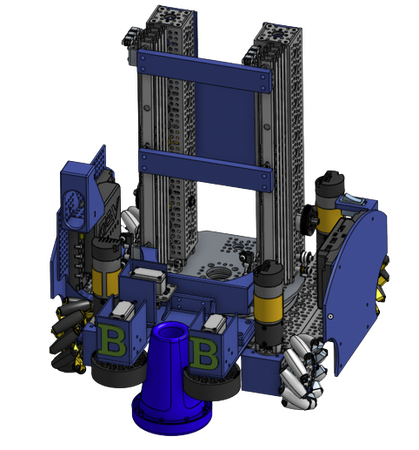

Power Play 2022-2023

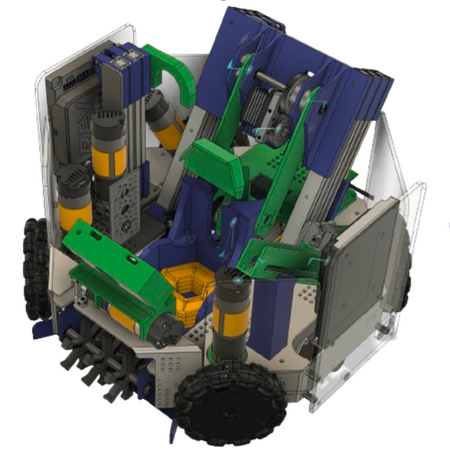

Center Stage 2023-2024

The Team

Emma

Senior

3rd FTC Season

Scouting

Mechanical

CAD

JD's Dog JC

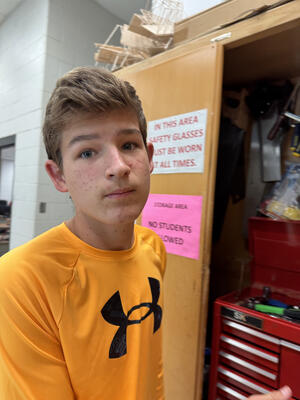

JD

Senior

3rd FTC Season

CAD

Programming

Mechanical

Xander

Junior

5th FTC Season

Programming

Eli

Sophmore

4th FTC Season

Mechanical

CAD

Caleb

Sophmore

2nd FTC Season

CAD

Mechanical

Dean

Sophmore

2nd FTC Season

Programming

Dylan

Sophmore

2nd FTC Season

Mechanical

Alex

Freshman

3rd FTC Season

Programming